Description

Control de motores:

• Portable flight-case format.

• Casing made of flexible polypropylene co-polymer with high impact resistance.

• Dimensions: Width: 470 mm. Depth: 355 mm (without connector). Height: 180 mm.

Electrical:

• Electrical supply: 24 V (DC)

• Control/power input: Harting industrial grade connector.

• Control/power cable: 4 x 2 x 0,13 mm² CAT 5e + 10 x 1 mm², 10 m long.

• Power consumption: 1 A.

Hardware:

• Display: 12,1” TFT touchscreen with 1024x768 pixels resolution.

• Processor : TPC – 1251 T.

• Communications with controllable devices: CanOPEN Network.

• Emergency stop switch.

• Playback with joystick.

• Backlit pushbuttons.

Software:

• General features:

- Custom single-core software completely developed in C# language, “disk on chip” executable.

- Software updates: via USB and ETHERNET port.

- Control Capacity: up to 32 axis.

- Graphical user interface: emerging windows based.

- Motor selection: via touchscreen.

- Two-dimension virtual visualization of working space and all controllable equipment.

- Edition of labels for flying-bars or other scenery elements.

- Alarm and system messages log.

- Status synoptic scheme for emergency push buttons.

• Functional features:

- Number of controllable drives: up to 32 variable speed type motors.

- Maximum motors in movement at the same time: 20 axis.

- Positioning on-screen display.

- Speed control.

- Manual control.

- Memories for synchronized groups of motors.

- Load Cell monitoring

• Controllable motor types:

- Fixed speed, inductive motors (with or without positioning control).

- Variable speed, inductive motors.

- Servomotors.

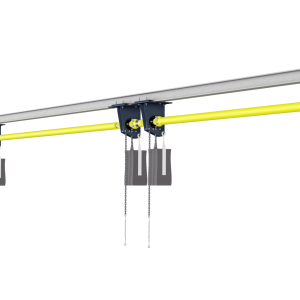

• Applications:

- Fixed or variable speed flying battens.

- Understage machinery such as lifts, wagons, revolving stages, etc.

- Motorized cable reels.

- Motorized acoustic curtains.

- Motorized curtain tracks.

Applicable regulations:

• Low Voltage Directive LVD 2006/42/CE

• EMC Directive 2004/18/CE

Designed and manufactured in compliance with:

• EN 17206/DIN 56950

• EN ISO 12100

• EN 60204-32